- English

- 日本語

Namura Taiseido was founded in 1940, when we began manufacturing and selling brushes for calligraphy, Japanese paintings, watercolors, oils, and more.

At the same time, we established the Japan Ink Brush Research Institute in order to not just manufacture and sell brushes, but to improve product quality and carry out our own independent research into brush technology.

In 1949, our first president, Haruo Namura, was given an appointment in the Ministry of Education’s School Children’s Materials Screening Committee, where he worked in the role of an expert to establish standards for ink (writing) brushes and art brushes.

In this way, Namura Taiseido has played a major role in improving and maintaining the quality of brush manufacturing in Japan, from the time of its founding to the present day.

The techniques used in making Namura brushes, with their credo of high quality, have played an important part.

We have carried out research on brush-making technology in order to unceasingly improve the quality of Namura brushes.

The deepest secrets of brush-making have been laid bare thanks to these years of research.

Here, as shown by the process by which we make hog-hair brushes for oil painting, is just a glimpse of those deep secrets.

Hog-hair brushes for oils are made from just a single type of hog hair, so it can be very hard to tell the differences between them in terms of appearance and tip structure.

The very first process in creating a brush tip for a hog-hair brush is thinning. This step is very important in determining how good the final brush will be.

Thinning refers to removing unwanted elements, so in terms of making a brush tip, it means the process of removing unwanted bristles, such as ones with rough tips or that curl in backwards.

If this is done without due care, then the odd bristle may stick out, creating unwanted marks on the artwork.

It will also mean that the tip does not come together well, making it impossible to paint details.

All this means that thinning is perhaps the single most important step in creating a brush tip, and how carefully this process is carried out determines how good the final brush will be.

At Namura Taiseido, we have emphasized this thinning step right from the time we first began to make brushes.

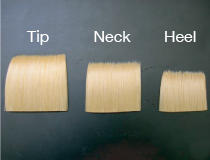

The most notable characteristic of a Namura hog-hair brush is the way the bristles at each part–the tip, the neck, the heel, –are carefully blended and balanced.

This blending process can be varied to give volume, or stiffness, or change the shape of the tip for different item numbers.

As shown above, bristles of different lengths are bound together into a single mixed bunch.

This mixing work is done on glass while lightly wetting the bristles.

By mixing the bristles together again and again while lightly wetting them, they become more tightly packed together, increasing their density, and creating a firm, precise toe.

It is the careful repetition of these steps that creates the dense, resilient brush tips of a Namura brush.

The nature of hog’s hair bristles gives them a tendency to curve back on themselves in an arch when moist, rather than point straight. This means that they need to have their shape formed in different way to softer bristles such as horse, ox, or weasel.

Ways to create a shape for bent bristles include wrapping or matching. For Namura hog-hair brushes, we use the wrapping method.

In the wrapping method, we use a tube called a koma that matches the brush size to measure the amount, and, using the tendency of the bent hog’s hairs to curl, we wrap each bunch around itself, evenly on both sides.

This method of making the bent bristles all curve towards the middle evenly offsets the hog’s hairs curls, and creating a smooth, straight tip.

The bristles are removed from the koma and bound with thread.

The bristles are removed from the koma and bound with thread.